Medical non-woven composite PE (Polyethylene) film is a specialized material used in various medical applications, particularly for its barrier properties, durability, and flexibility. The composition and structure of this material can vary depending on its intended use, but here are the basic components and structure typically found in medical non-woven composite PE film:

Polyethylene (PE) Layer:

The core component of the film is the polyethylene layer. PE is a synthetic polymer known for its flexibility, moisture resistance, and chemical resistance.

Depending on the specific requirements of the medical application, different types of PE may be used, such as low-density polyethylene (LDPE), high-density polyethylene (HDPE), or linear low-density polyethylene (LLDPE).

Non-Woven Fabric Layer:

A non-woven fabric layer is often laminated onto one or both sides of the PE film. This layer is typically made of synthetic fibers (polypropylene, polyester) or natural fibers (cotton, rayon) that are bonded together without a traditional weaving process.

The non-woven fabric layer provides added strength, stability, and a textile-like texture to the film. It can enhance the tear resistance and overall performance of the material.

Adhesive Layer (if applicable):

In some cases, an adhesive layer may be used to bond the non-woven fabric to the PE film. This adhesive is selected for its biocompatibility and ability to securely join the layers without compromising the barrier properties.

Structure:

The structure of medical non-woven composite PE film typically involves a multilayer arrangement, with the non-woven fabric layer(s) laminated to the PE core layer. The specific structure can vary based on the desired properties and applications. Here's a simplified representation of the structure:

Outer Layer (Non-Woven Fabric):

This is the outermost layer of the composite film.

It provides a textured and fabric-like surface that can be gentle on the skin and suitable for contact with patients.

Intermediate Layer (Adhesive, if applicable):

In cases where an adhesive layer is used, it sits between the non-woven fabric and the PE film, securely bonding them together.

Core Layer (Polyethylene Film):

The core layer is typically made of PE, providing a moisture-resistant barrier.

PE film is known for its flexibility, making it easy to drape over body parts or medical equipment.

Inner Layer (Non-Woven Fabric, if applicable):

In some designs, an additional non-woven fabric layer may be laminated to the opposite side of the PE film.

This inner layer can provide added strength and stability to the film and may also offer a soft surface for patient comfort.

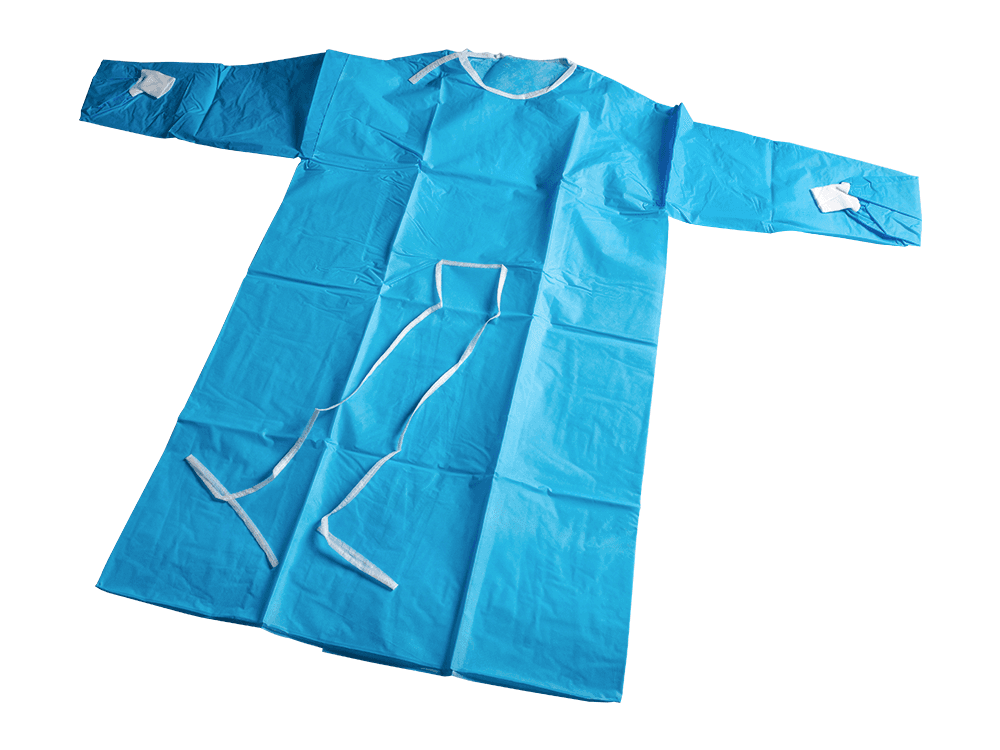

Medical non-woven composite PE film is used in various medical products, such as surgical drapes, gowns, disposable bed linens, and wound dressings. Its composition and structure are carefully selected to meet specific requirements for hygiene, barrier protection, comfort, and durability in medical settings.

english

english 中文简体

中文简体