Non-woven composites are extremely popular due to their versatility and cost efficiency. Various methods are used for their manufacture, including adhesive bonding, thermobonding and direct extrusion (cast method).

The latter produces low linting laminates that offer good isolation performance. However, their breathability is poor and their risk of pinholes is high.

Strength and Softness

PE film is a highly flexible and strong material that can be used for many applications. It resists water, dust, chemicals, heat, and punctures. Non-woven Composite PE Film are also lightweight and have a soft touch.

Nonwovens are produced by putting together small fibers into sheets or webs. They are then bound mechanically or thermally, using binder. The binders can be made from natural or synthetic materials, such as cellulose or starch. They can be made with different coatings and are available in a variety of colors.

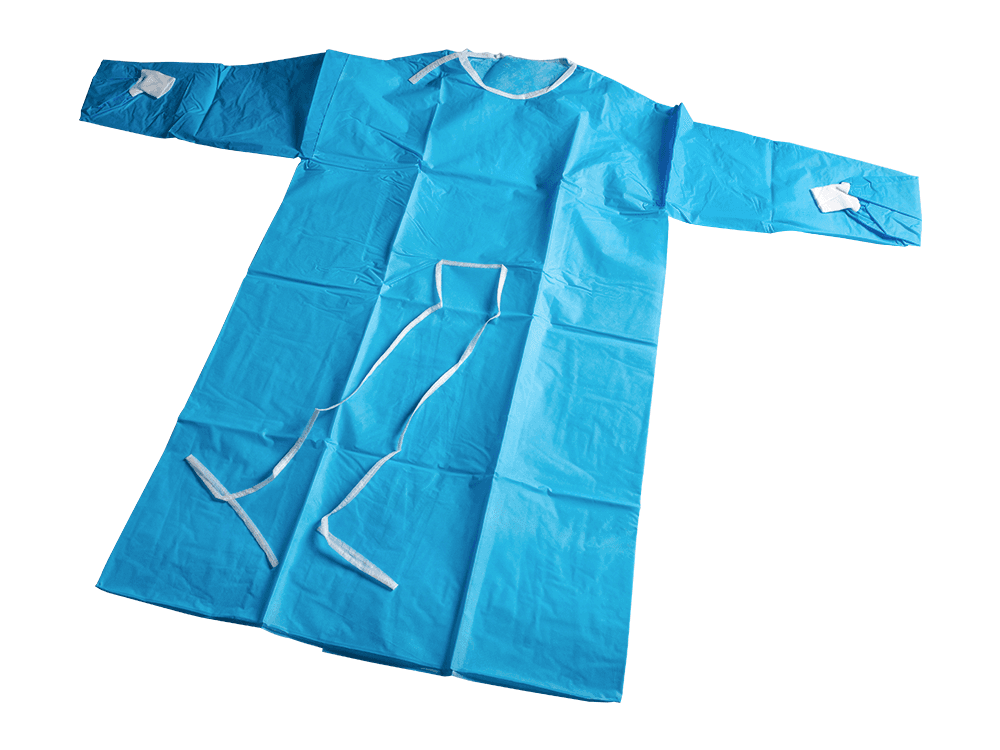

Medical nonwovens are often used for surgical gowns, clinical wearables, and wipes. They can also be used in wound dressings, swabs, pads, and hernia meshes. These products are designed to be safe for use in hospitals and provide protection and comfort. They are also lightweight and have high tensile strength. They also have a good insulation performance and can be sterilized. In addition, they are soft and breathable. They are also available in a wide range of thicknesses.

Breathability

Breathable composites of filled linear polyolefin film laminated to a fibrous nonwoven are often difficult to form because the polymers forming the nonwoven and the film layers are thermally incompatible. In addition, conventional methods of bonding the film to the nonwoven such as gluing, needling and sewing can result in a poor composite fit that may significantly restrict liquid flow and/or block the breathable film pores.

The invention provides a process for forming a breathable film/nonwoven composite by incorporating a bonding additive in the breathable film polymer blend and a bonding additive in the polymer mix forming the fibers in the nonwoven comfort layer. In the examples described herein, the comfort layer is formed from a polypropylene spunbond web with single component fibers and bicomponent fibers including side-by-side and sheath/core fibers.

The fibrous nonwoven support layer is bonded to the breathable film using heat and pressure. The resulting composite has excellent MD and TD strength to reinforce the breathable film, high tensile and tear strengths for strength and integrity, good flexural properties to allow the fabric to resist abrasion and stretch and breathability to permit liquid flow through the open structure of the fibrous comfort layer.

Thermobonding

Thermobonding is a technique in which the film and nonwoven are bonded through a thermal process. In contrast to adhesive bonding, which entails a bonding of the whole surface of both the film and the nonwoven, this method allows a localized bonding and therefore preserves breathability and composite strength.

The PP+PE film laminated with nonwoven fabrics is often used in medical applications, such as surgical gowns and aprons. This is because it has high isolation performance, and also can be made flame retardant by adding a special masterbatch.

The thermobonding method according to the invention can be carried out using a standard extrusion plant. A melt PE raw material is sprayed uniformly on the surface of a PP spunbond nonwoven, and after cooling, one new type of composite non-woven fabric is formed. This is the base for many different kinds of disposable medical products and packs. The resulting breathable composite has both a smooth PP surface and a rough PE surface, making it very durable and easy to clean.

Printing

Unlike woven fabrics or knitted fabric, nonwovens are flat or tufted porous sheets that can be made directly from separate fibres or molten plastic without converting them to yarn. They are bonded mechanically, thermally or chemically.

Medical non-wovens are mainly used for disposable surgical packs to prevent patient-to-patient transmission of resistant pathogens such as MRSA and vancomycin-resistant enterococcus (VRE). They must be extremely low linting, have clothlike feel, easy handling properties and good barrier functions.

The present invention provides a non-woven fabric laminate of PP and PE with low linting, excellent barrier function and good softness and compressibility. The PP surface of the non-woven is pre-treated with hydrophilic agent to improve its water absorbency, while the PE surface is responsible for high barrier functions.

Moreover, the novel PE spun-bonded non-woven is not only extremely soft and has good compressibility but also can be easily composited with an air permeable film by heating, thereby eliminating the need for additional adhesive materials. This can provide a new solution for many automotive applications such as seat trim, car mats and truck bed liners.

english

english 中文简体

中文简体